One stop solutions

Integrated Services

- Product development

We assist you to bring your ideas into reality with agreed quality at competitive cost. We are able to provide recommendations to customers to make right decision on the investment on the tooling and competitive production cost. We are able to assist in 3D modelling and supply prototypes when required.

- Mould making

We work closely with highly skilled mould makers to provide high quality moulds. From short run production tooling to hardening steel mould for high volume production, we are able to provide competitive prices on moulds.

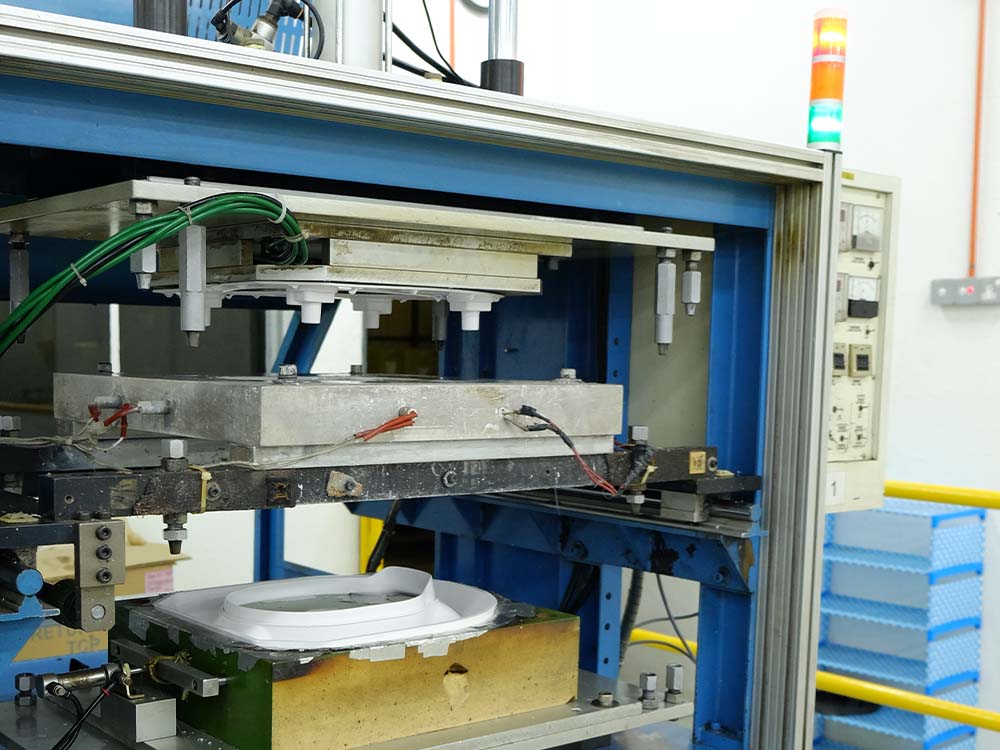

- Plastic injection moulding

We are equipped with complete range of injection moulding machines ranging from 50 tons to 650 tons in injection pressure to enable us to provide you with different options for your requirements. We mould parts from commodity thermoplastics to engineered resins.

We are experienced to run insert moulding, over moulding and runnerless moulding. Our in house tooling workshop is able to provide mould maintenance periodically to your moulds.

We works with established material suppliers to provide balance of properties of your application needs.

Below are common materials we used to run:-

- ABS

- PA

- PC

- PMMA

- PP

- PS

- Composite materials (PPGF, PAGF, PPCC, PCABS, PPFR)

- Plastic injection moulding

We are equipped with complete range of injection moulding machines ranging from 50 tons to 650 tons in injection pressure to enable us to provide you with different options for your requirements. We mould parts from commodity thermoplastics to engineered resins.

We are experienced to run insert moulding, over moulding and runnerless moulding. Our in house tooling workshop is able to provide mould maintenance periodically to your moulds.

We works with established material suppliers to provide balance of properties of your application needs.

Below are common materials we used to run:-

- ABS

- PA

- PC

- PMMA

- PP

- PS

- Composite materials (PPGF, PAGF, PPCC, PCABS, PPFR)

- Sourcing of sub components

We have dedicated team to assist in sourcing of sub components that required to complete the final products. We have been helping customers to source sub components for many years, whether it is from Malaysia or oversea countries.

- Special Finishing

We provide wide range of secondary and finishing processes in house. Our facilities include vacuum metalizing, spray painting, hot stamping, hot plate welding, ultrasonic, pad printing and silkscreen to enhance the plastic parts.

- Assembly & Packing

Emico is equipped with assembly lines to assemble plastic parts and sub-components with required labelling and packaging. Both of our assemble workstations and assembly lines will able to fulfill your needs.

We are strong in components sourcing such as hardware, metal die casting and extrusion components, stamping parts to integrate into the complete products. Customers are welcome to send in their own components.

We work closely with packaging suppliers for final packing/delivery solutions from consumer to palletized packaging.

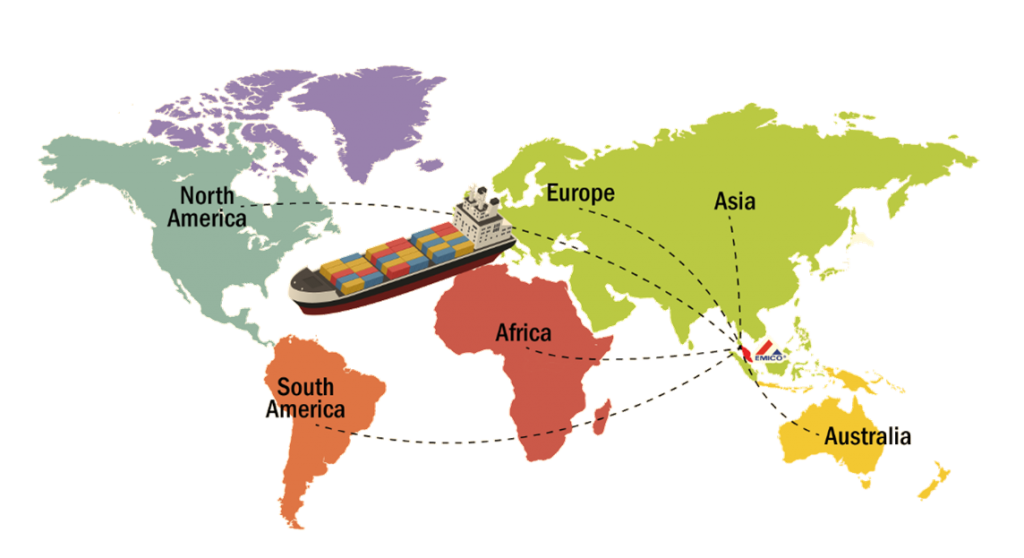

- Global Distribution

We have a dedicated team to support your logistic arrangement. We have vast experience in handling export activities as we have shipped to over 45 countries as at today. Averagely we ship 5 containers weekly to different countries all over the world.

The next thing is yours...

Tell us your concepts and ideas. We’ll provide you consultation for FREE.